Thermal Transfer Barcode Ribbon

populary known as TTR and used in any of the thermal transfer printers, specially for barcode industry , fax industry, point of sales industry,

we have wax,

wax resin

resin

washcare,

near edge

scratch ribbons

colour wax ribbons

Similar Products

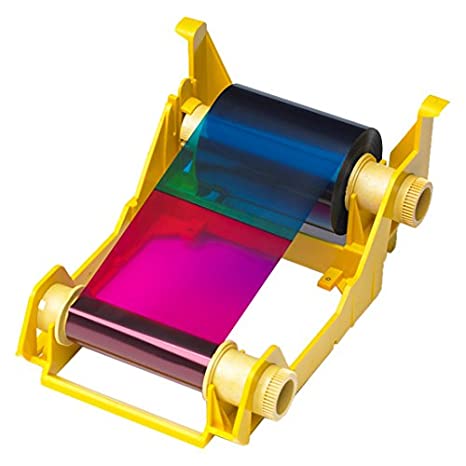

PART NUMBER - 800033-340IN Manufacturer Part Number: 800033-340 Compatible with the Zebra ZXP Series 3 Card Printer Prints 280 single-sided cards per ribbon YMCKO full-color ribbon Printer firmware and driver version must be 2.0 or

PROVIDES GOOD ABRASION AND CHEMICAL RESISTANCE With top-coated paper and matte synthetic materials In environments with moderate to harsh exposure to chemicals and/or abrasion

UNMATCHED PRINT QUALITY AND DURABILITY With all synthetic materials and some topcoated labels and tags In environments with harsh to extreme exposure to chemicals When applications require strong resistance against ultra high temperatures a

WORKS BEST FOR MOST APPLICATIONS With paper materials Where fast print speeds are required (Up to 12 ips) In environments with little to no exposure to chemicals and/or abrasion