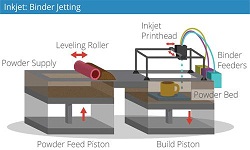

Inkjet Printing

The additive fabrication technique of inkjet printing is based on the 2D printer technique of using a jet to deposit tiny drops of ink onto paper. In the additive process, the ink is replaced with thermoplastic and wax materials, which are held in a melted state. When printed, liquid drops of these materials instantly cool and solidify to form a layer of the part. For this reason, the process if often referred to as thermal phase change inkjet printing. Inkjet printing offers the advantages of excellent accuracy and surface finishes. However, the limitations include slow build speeds, few material options, and fragile parts. As a result, the most common application of inkjet printing is prototypes used for form and fit testing. Other applications include jewelry, medical devices, and high-precisions products. Several manufactures have developed different inkjet printing devices that use the basic technique described above. Inkjet printers from Solidscape Inc., such as the ModelMaker (MM), use a single jet for the build material and another jet for support material. 3D Systems has implemented their MultiJet Moldeling (MJM) technology into their ThermoJet Modeler machines that utilize several hundred nozzles to enable faster build times.

The inkjet printing process, as implemented by Solidscape Inc., begins with the build material

Inkjet Printing

(thermoplastic) and support material (wax) being held in a melted state inside two heated reservoirs. These materials are each fed to an inkjet print head which moves in the X-Y plane and shoots tiny droplets to the required locations to form one layer of the part. Both the build material and support material instantly cool and solidify. After a layer has been completed, a milling head moves across the layer to smooth the surface. The particles resulting from this cutting operation are vacuumed away by the particle collector. The elevator then lowers the build platform and part so that the next layer can be built. After this process is repeated for each layer and the part is complete, the part can be removed and the wax support material can be melted away.

Similar Products

MINDWARE is an Importer and Distributor of AURA PP-6900U POS Printer of best Prices and we also provide Service support for AURA PP-6900U POS Printer. Get the best prices for AURA PP-6900U POS Printer from INDIANBARCODE CORPORATION, call at +91981

MINDWARE is an Importer and Distributor of AURA PP-6907W POS Printer of best Prices and we also provide Service support for AURA PP-6907W POS Printer. Get the best prices for AURA PP-6907W POS Printer from INDIANBARCODE CORPORATION, call at +9198

MINDWARE is an Importer and Distributor of AURA PP-8802 POS Printer of best Prices and we also provide Service support for AURA PP-8802 POS Printer. Get the best prices for AURA PP-8802 POS Printer from INDIANBARCODE CORPORATION, call at +91981082

- MINDWARE is an Importer and Distributor of AURA PP-8803 POS Printer of best Prices and we also provide Service support for AURA PP-8803 POS Printer. Get the best prices for AURA PP-8803 POS Printer from INDIANBARCODE CORPORATION, call at +91981